- check Managing Director: Fereidoun Kayhani

- check Date of foundation: 1973

- check Phone: (+9821) 88914926-30

- check Fax: (+9821) 88809839

- check E-mail: info@nargan.com

- check Website: www.nargan.com

- check Address: No. 211, Taleghani Ave., Tehran 1598917431- Iran

Company Motto

We have the Solution!

- Company Background

- Areas of Activity

- Human Resources

- Achievements

- Infrastructures

- Previous Project List

- International Cooperation

Company Background

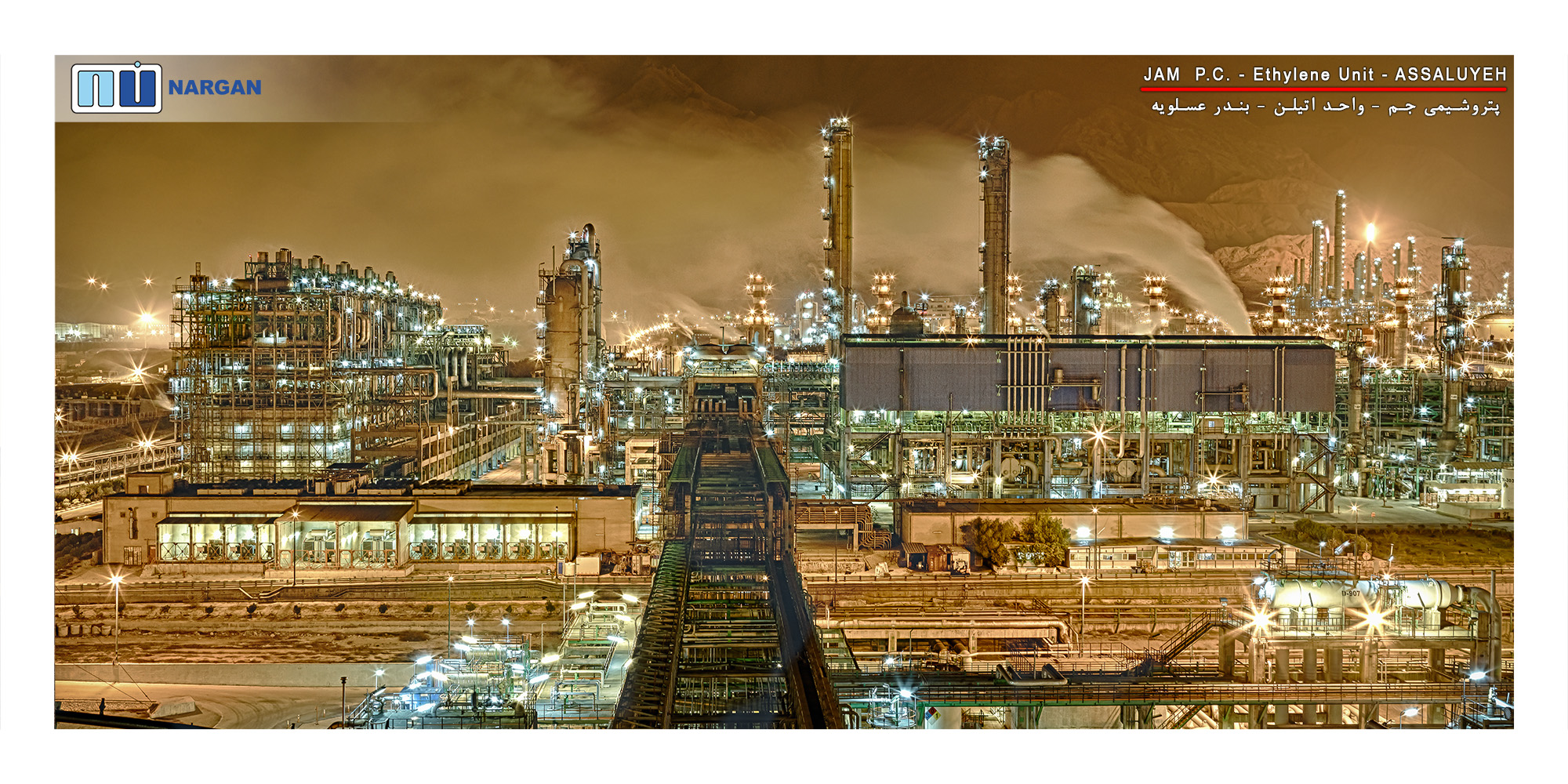

NARGAN, as a privately owned company, is an engineering, procurement, construction, and project management company in the design and development of industrial projects, particularly in the oil, gas and petrochemical fields. NARGAN Company was established in 1973 under the name of BORNAA Consulting Engineers. It was the first Iranian company active in upstream and downstream sectors of oil, gas and petrochemistry industry right from the start.

Areas of Activity

NARGAN has been active in the design, procurement and construction of a multitude of oil refineries, gas treatment facilities and petrochemical complexes; and provides a full spectrum of services mainly in the following fields:

Oil & Gas Fields Development (Integrated Subsurface and Surface Engineering)

- Full Filed Development Studies

- Core & Well log analysis

- Basic Reservoir Engineering

- Dynamic Modeling

- Uncertainty Analysis and History Matching

- Production Forecasting

- Flow Assurance

- Artificial Lift Design

- Material Selection

- Production Chemistry

Upstream Surface Facilities

- Offshore/Onshore Platforms

- Production Plants

- Offshore/Onshore Pipelines

Gas Process Facilities

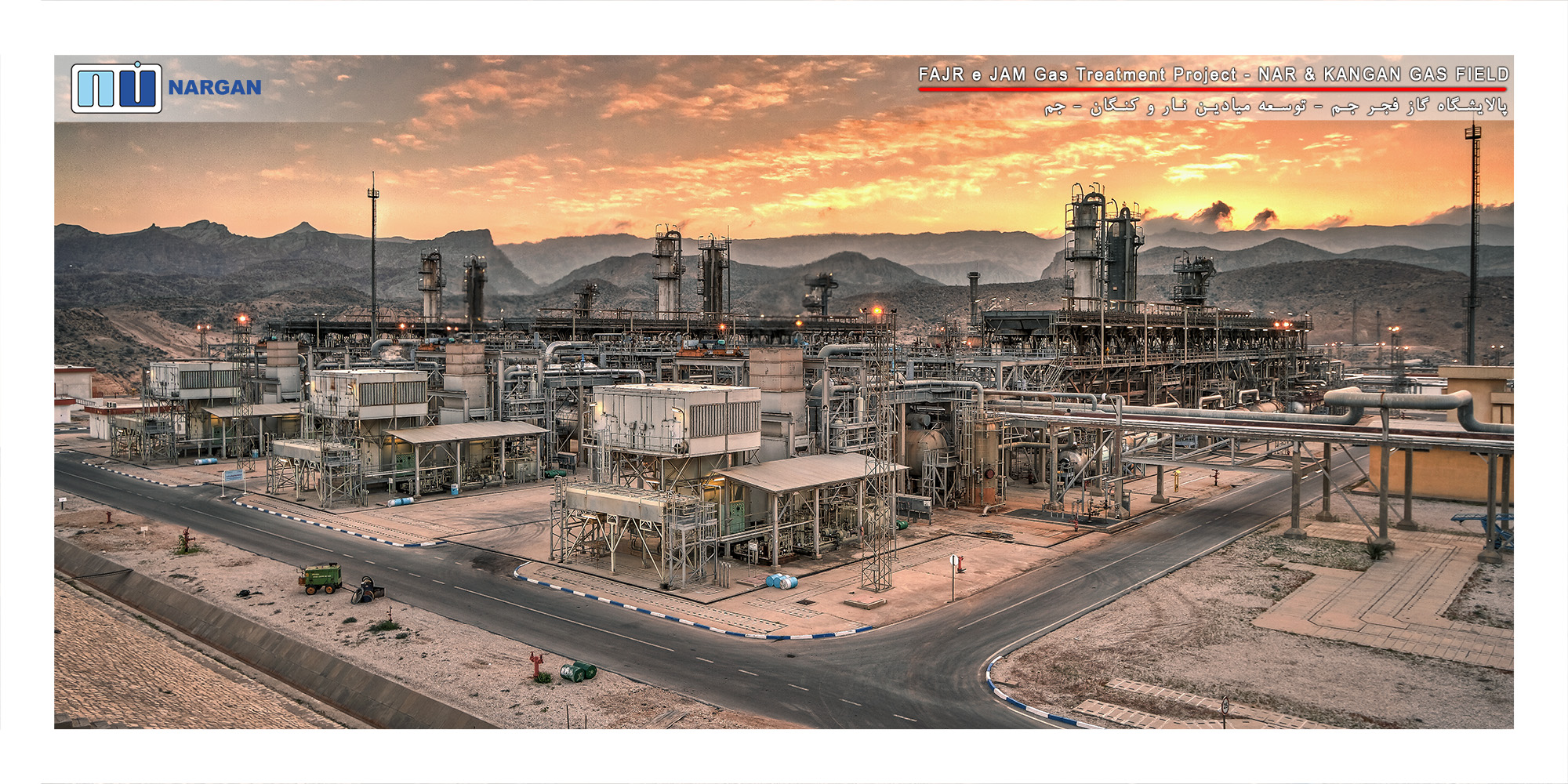

- Gas Refineries & Treatment Facilities

- Gathering Systems

- Injection Systems

Oil Process Facilities

- Crude Oil Refineries

- Condensate Refineries

Petrochemical & Chemical Complexes

- Ethylene Plants

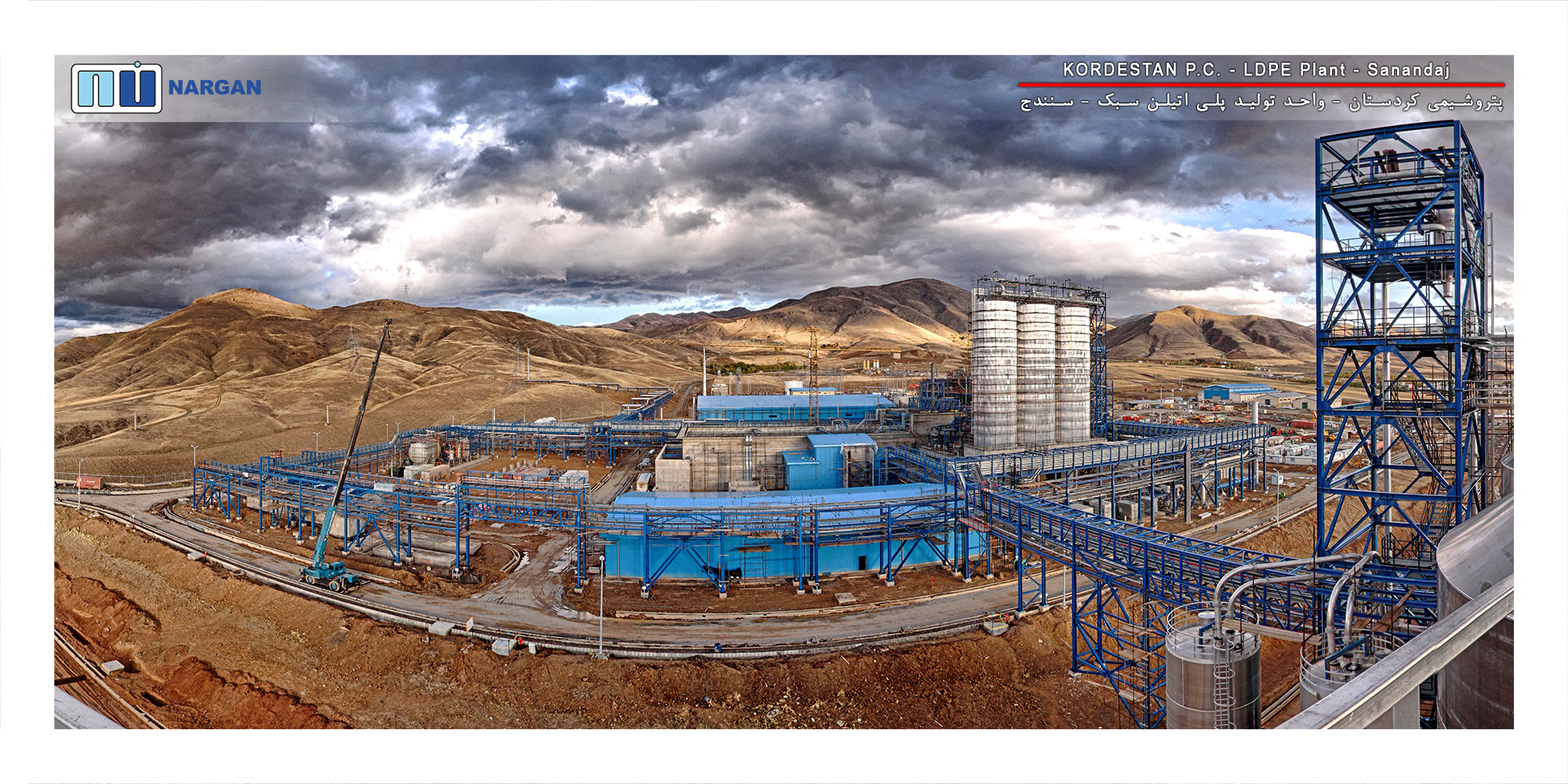

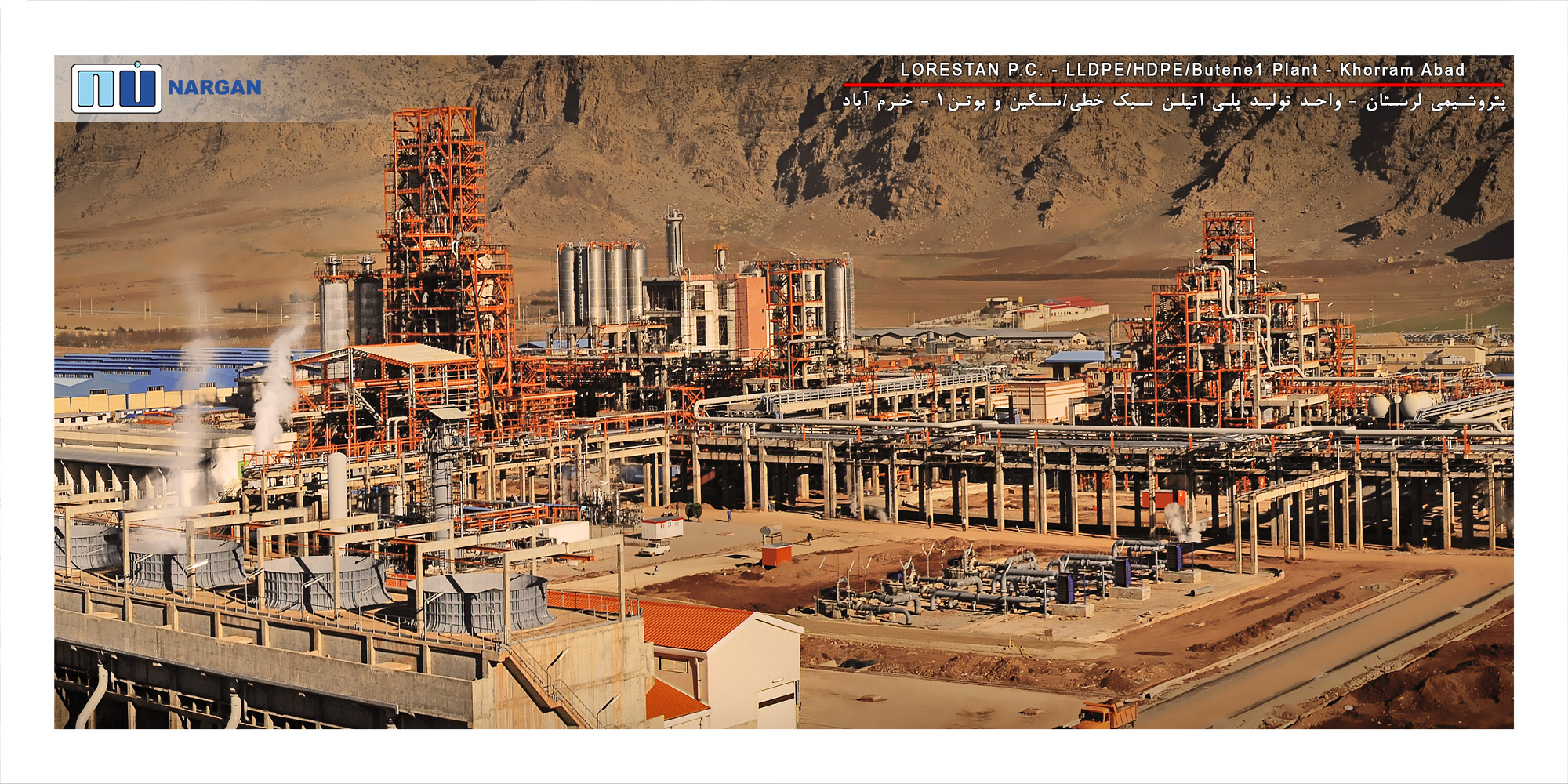

- Polyolefins (PE & PP) Plants

- Polymers & Artificial Rubbers Plants

- Chemical Fertilizers; and

- Various Other Plants

Infrastructures

- Plant Utilities

- Electric Power Generation & Distribution

- Terminals & Storages

- Water Treatment & Desalination Systems

- Waste Water Treatment

- General Industrial Developments

& Transportation & Pipeline Systems

Human Resources

NARGAN has one of the largest engineering resource pools in Iran with around 700 to 1000 currently highly skilled professionals in across 10 engineering disciplines and other organizational expertise including project management. Over half of company people hold graduate degrees or higher in engineering and science.

Achievements

NARGAN has earned our reputation over more than 48 years of high quality work, encompassing safe and on time delivery of more than 300 completed projects.

- The biggest olefin, ethane recovery and gas treatment plant

- Over 60 local and foreign clients

- More than 10,000,000 engineering man-hours

- Cooperation with 25 international companies

- Over 5.0€ billion contract value

- 420 MMSCMD of Gas Production & Treatment Facilities

- 102 MMSCDM of Gas Separation Facilities

- 1,000,000 BPSD of Crude Oil Production Facilities

- 7,900,000 TPA of Olefins Plants

- 2,760,000 TPA of Poly-Olefins Plants

- 1,600,000 TPA of Various Petrochemical Products

- Over 4,000 km of Oil/Gas/Products/ Ethylene Pipeline and the Associated Pumping & Compressor Stations

NARGAN has been achieved the below technical certificates:

IPMO’s Certificates

issued by Iranian Planning and Management Organisation

- Engineering Certificate (Grade 1 in Oil, Gas & Petrochemical Complexes and Pipelines; Grade 2 in Upstream Surface Facilities)

- Design & Built (EPC) Certificate (Grade 1 in Oil & Gas Sector)

- Construction Certificate (Grade 1 in Oil & Gas Field)

IMI’s Certificate

issued by Industrial Management Institute

- EPC Certificate (Grade A in Oil, Gas & Petrochemical Sector)

Ministry of Labor & Social Affair’s Certificate

- HSE Certificate

- HSE Policy

Infrastructures

The Integrated Management System applies to the whole organisation of NARGAN Company including offices and projects’ sites. Our products and services are in compliance with ISO 9001:2015, ISO/TS 29001:2010, ISO 14001:2015 and ISO 45001:2018 (Previously OHSAS 18001:2007).

We are committed to maintaining its Quality Management System in accordance with ISO 9001 certificate, conferred on us since 2004.

Given the fact that we improve continuously our quality system through periodic review and assessments, we have also been granted since 2013 the ISO/TS 29001 certificate, which is based on ISO 9001 quality management system providing all requirements for the petroleum, petrochemical, and natural gas industries. Further, our quality credentials also include ISO 14001 and OHSAS 18001 certificates which we have held since 2008.

NARGAN’s risk based IMS aims all interested parties’ satisfaction and continual improvement as far as sustainable success strategy, implemented in the organisation. These establishments demonstrate the company’s ability to meet all requirements in compliance with applicable laws, regulations and guidelines in order to mitigate or eliminate the risks’ impacts also to benefit from any available potential opportunities.

NARGAN has been equipped with a standard multilayer CAN (Campus Area Network) that provides enterprise level services. Network resources can be accessed locally and worldwide through high speed dedicated Internet connections. Mutual data transfer with joints in projects will be feasible via radio links. All standard methods and latest practices have been implemented to protect NARGAN’s information asset.

General IT Services like email and file service -local and global, internet access, office apps, video conferencing software and programs, CAD, print & plot setting and 2D & 3D modeling have been are provided to internal users. Furthermore, advanced in-house applications have been developed and launched for ease of doing the job by our engineering and project teams.

NARGAN’s PCIM (Project Central Information Management) -a well-known web application- has been developed to support easy collaboration between all project bodies- encompassing clients, management consulting (MC), subcontractors and vendors- via EDMS (Electronic Document Management System). It provides a secure way to store, share and transfer files and documents between all bodies involved in the project based on a pre-defined collaboration matrix with transmittals.

Some of the NARGAN’s hardware and software specifications has been shown in below:

Hardware

• Servers: 66

• Work Station: 1045

• Switch: 122

• UTM: 10

• Wireless Router: 9

• IT Tower: 1 (39 m Height)

Software

• General SW: 20 (Main)

• Engineering SW: 73

• Technical SW: 15

Previous Project List

List of Projects with engineering services in the past ten years

| No. | CLIENT | DESCRIPTION |

| 1 | SAZEH-JAHANPARS CONSTRUCTION FOR BID BOLAND 2 PROJECT | REVIEW OF MATERIAL SELECTION DIAGRAM 3D MODELING AND HAZARDOUS AREA CLASSIFICATION |

| 2 | ANAHITA OIL REFINARY CO. /KBC (UK) | BASIC ENGINEERING DESIGN PACKAGE FOR VISBREAKER UNIT OF ANAHITA OIL REFINARY |

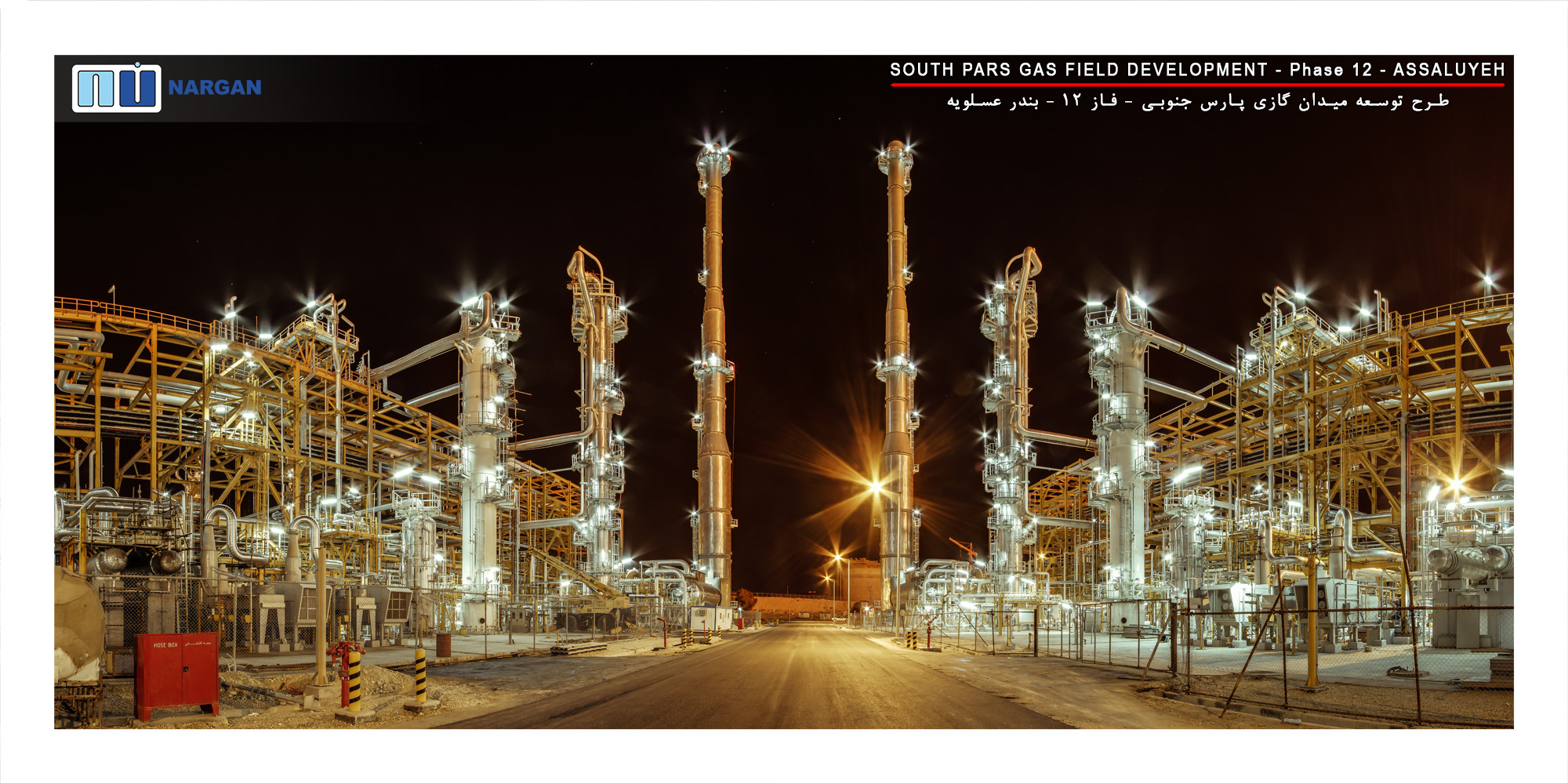

| 3 | PETROPARS CO. | ENGINEERING, PROCUREMENT,CONSTRUCTION,PRE-COMMISSIONNING,COMMISSIONING,START-UP AND PERFORMANCE TEST,ON SHORE GAS PROCESSING UNIT(EPC-3) FOR PROCESSING 3000 MMSCFD FEED SOUTH PARS GAS FIELD DEVELOPMENT ,PHASES 12 |

| 4 | PETRO SINA ARIA | FRONT END ENGINEERING DESIGN (FEED) ,DETAILED ENGINEERING AND PROCUREMENT SERVICES.SOUTH PARS FIELD DEVELOPMENT ,I) PHASES 22,23,24 II) PHASES 13 ONSHORE PROCESSING PLANTS.PRODUCTION FOR EACH PLANT: 50 MMSCM/D TREATED GAS 2.21 MMSCM/D ETHANE 40,000 B/D CONDENSATE. |

| 5 | PETROPARS IRAN | FRONT END ENGINEERING DESIGN (FEED) ,DETAILED ENGINEERING AND PROCUREMENT SERVICES.SOUTH PARS FIELD DEVELOPMENT, PHASES 19 ONSHORE PROCESSING PLANTS.PRODUCTION FOR EACH PLANT: 50 MMSCM/D TREATED GAS 2.21 MMSCM/D ETHANE 40,000 B/D CONDENSATE. |

| 6 | ARYA SASOL POLYMER CO. | PERFORMANCE OF BASIC & DETAIL ENGINEERING FOR C3 EXPORT PIPELINE |

| 7 | BUSHEHR PETROCHEMICAL COMPANY | BASIC AND DETAIL ENGINNERING, PROCUREMENT ENGINEERING, CONSTRUCTION SUPERVISION AND TECHNICAL ASSISTANCE SERVICES 1000000 TPA ETHYLENE PLANT |

| 8 | IRANIAN CENTRAL OIL FIELDS COMPANY (ICOFC) | MANAGEMENT CONSULTANCY SERVICES FOR FARASHBAND GAS TREATMENT FACILITIES DEVELOPMENT PROJECT |

| 9 | SATA COMPANY | INTERCONNECTING PIPELINES BETWEEN SOUTH PARS PHASE 12 CTP AND C2+ RECOVERY AND FRACTIONATION PLANT |

| 10 | SADAF ASSALOUYEH CHEMICAL COMPANY | DETAIL ENGINEERING, PROCUREMENT SERVICES, SUPPLY OF EQUIPMENT (AND MATERIAL), TECHNICAL ASSISTANCE AND SUPERVISION SERVICES FOR 136 KTPA ESBR PLANT |

| 11 | FARZANEGAN FARS NIKOO | TECHNICAL SUPERVISION FOR PREPARATIONOF PDP FOR GAS CONDENSATE REFINARY (10,000 BBLD) |

| 12 | FALCON ENERGY, NARGAN, SAZEH | ENGINEERING DESIGN SERVICES, PROCUREMENT & SUPPLY, CONSTRUCTION WORK AND COMMISSIONING FOR 60,000 BPSD CONDENSATE REFINERY IN SIRAF REFINERIES PARK, ASSALUYEH |

| 13 | BIOSUN PHARMED COMPANY | REVIEW OF BASIC & DETAIL ENGINEERING AND PERFORMANCE OF HOME OFFICE AND SITE SUPERVISION |

| 14 | SIRAF REFINERIES INFRASTRUCTURE COMPANY | MAN-POWER ASSIGMENT CONTRACT FOR CONDENSATE REFINERIES IN SIRAF REFINERIES PARK, ASSALUYE |

| 15 | FAJR-JAM GAS REFINING CO. | FEASIBILITY STUDY AND BASIC ENGINEERING DESIGN SERVICES FOR SOUTH PARS GAS TREATING IN KANGAN GAS REFINARY |

| 16 | BADR-E SHARGH PETROCHEMICAL COMPLEX | FEASIBILITY STUDY FOR GTO+ COMPLEX (BADR-E SHARGH PETROCHEMICAL COMPLEX) |

| 17 | HORASSAN PETROCHEMICAL COMPLEX | FEASIBILITY STUDY FOR NEW AMMONIA UREA & CRYSTAL MELAMINE PLANT |

| 18 | GACHSARAN PETROCHEMICAL COMPANY | FEASIBILITY STUDY, CONCEPTUAL DESIGN |

| 19 | PERSIAN GULF BID BOLAND GAS REFINING CO. | FEASIBILITY STUDY (FS) AND CONCEPTUAL DESIGN FOR NGL 1800 AND NGL 2400 |

| 20 | BADR-E SHARGH PETROCHEMICAL COMPLEX | CONSTRUCTION MANAGEMENT AND SITE SUPERVISION FOR 1,650,000 TPA METHANOL PLANT IN MOKRAN PETROCHEMICAL PARK |

| 21 | PETROPARS CO. | FARZAD A GAS FIELD STUDIES –ELEMENTAL SULFUR STUDY AND PVT ANALYSIS |

| 22 | PETROPARS CO. | EVALUATION OF ROCK/WATER INTERACTION: FORMATION DAMAGE- SOUTH PARS GAS FIELD |

| 23 | IRANIAN OIL OFFSHORE COMPANY | CONCEPTUAL STUDY AND FIELD STDUIES RESHADAT AND ESFAND FIELDS– SMART WATER INJECTION |

| 34 | IRANIAN OIL OFFSHORE COMPANY | CONCEPTUAL STUDY NASR PLATFORM FIELD STUDIES – ASSOCIATED GAS PRODUCTION DEBOTTLENECKING |

| 25 | IRANIAN CENTRAL OIL FIELDS COMPANY | CONCEPTUAL STUDY KANGAN GAS LINE PRODUCTION DEBOTTLENECKING |

| 26 | IRANIAN OIL OFFSHORE COMPANY | FULL FIELD STUDY, MASETR DEVELOPMENT PLANNING, AND CONCEPTUAL DESIGN OF SURFACE FACILITIES – HENDIJAN OIL FIELD |

List of Projects with engineering services in more than ten years

| No. | CLIENT | DESCRIPTION |

| 1 | NATIONAL IRANIAN OIL COMPANY | DETAILED ENGINEERING IMPROVMENTS TO ELECTRICAL DISTRIBUTION SYSTEMS OF HG-1,AZ-4,PZ-2,&MN-1 PRODUCTION UNITS |

| 2 | NATIONAL IRANIAN OIL COMPANY | PROCUREMENT SERVICES, LOCALLY SUPPLIED EQUIPMENT&MATERIALS.IMPROVMENTS TO ELECTRICAL DISTRIBUTION SYSTEMS OF HG-1,AZ-4,PZ-2,&MN-1 PRODUCTION UNITS,PROJECT |

| 3 | MESBAH ENERGY COMPANY | CONSTRUCTION MANAGEMENT &SITE SUPERVISION QATRAN PROJECT |

| 4 | NATIONAL IRANIAN OIL COMPANY | ETHANE EXTRACTION FROM NATURAL GAS FOR PETROCHEMICAL FEEDSTOCK |

| 5 | MANPA CO. | ENDORSEMENT OF BASIC ENGINEERING,DETAIL ENGINEERING & CONSTRUCTION SUPERVISION UTILITIES,SOUTH PARS GAS TREATMENT PLANT-PHASE I (ASALUYEH REFINERY,PHASE 1) |

| 6 | NATIONAL IRANIAN OIL COMPANY/FIELDS | FIELD ENGINEERING&TECHNICAL ASSISTANCE RAMSHIR GAS INJECTION PROJECT |

| 7 | MINISTRY OF OIL | STUDY,42″AGHAR-DALAN GAS PIPELINE |

| 8 | NATIONAL IRANIAN GAS CO. | BASIC&DETAIL ENGINEERING&PROCURMENT SERVICES,OFFSITE FACILITIES MASJED-E-SOLEIMAN TREATMENTPLANT |

| 9 | TECHNIP | ENGINEERING SERVICES SOROOSH &NOWROOZ FIELD DEVELOPMENT PROJECT |

| 10 | PARS PETROCHEMICAL CO. | FEED GAS PIPELINES SYSTEM, PARS PETROCHEMICAL COMPLEX |

| 11 | NATIONAL IRANIAN GAS CO. | CONSTRUCTION MANAGEMENT &SITE SUPERVISION MASJED -E- SOLEIMAN GAS TREATMENT PLANT |

| 12 | NATIONAL PETROCHEMICAL CO. | FEASIBILITY STUDY :TREATMENT OF SOUTH PARS GAS AT FAJR REFINERY |

| 13 | PARS PETROCHEMICAL CO. | BASIC&DETAILED ENGINEERING&PROCURMENT& SUPPLY OF EQUIPMENT & CONSTRUCTION, ERECTION, PRECOMMISSIONING, COMMISSIONING, START -UP AND PERFORMANCE TESTS OF 300,000T/Y LDPE PLANT, BANDAR ASSALUYEH. |

| 14 | NATIONAL PETROCHEMICAL CO. | ETHANE /ETHYLENE PIPELINE STUDY ,BANDAR ASSALUYEH TO LORESTAN/ KERMANSHAH/KORDESTAN/AZARBIJAN PROVINCES |

| 15 | ESFAHAN PETROCHEMICAL CO. | CONSTRUCTION OF 40,000 TONS/YEAR PHTHALIC ANHYDRIDE PLANT IN ESFEHAN PETROCHEMICAL COMPLEX |

| 16 | PETROLEUM ENGINEERING & DEVELOPMENT CO.(PEDEC) | BASIC&DETAIL ENGINEERING AZADEGAN OIL FIELD CRUDE OIL TRANSFER PIPELINE |

| 17 | TECHNIP-FRANCE | SECONDMENT OF PERSONNEL TO TECHNIP ,FRANCE PARS LNG “FEED” |

| 18 | TOTAL | BASIC ENGINEERING ADMINSTRATION &PLANT AREAS BUILDINGS PARS LNG “FEED” |

| 19 | FAJR REFINARY | FEASIBILITY STUDY,PROCESSINGOF SOUTH PARS GAS,FAJR REFINERY |

| 20 | HYDRO ZAGROS OIL & GAS | AHVAZ EXPORT PIPLINE STUDY, CROSSING STUDY, AZAR FIELD DEVELOPMENT |

| 21 | N.I.O.E.C. | CONSTRUCTION SUPERVISION,DE-BOTTLENECKING OF BANDAR ABBAS REFINERY EXPANSION & RELATED PROJECTS |

| 22 | OIL DESIGN AND CONSTRUCTION COMPANY | REVIEW OF BASIC ENGINEERING, DETAIL ENGINEERING AND PROCUREMENT SERVICES |

| 23 | NIOC-SOUTHERN FIELDS CO. | PROJECT MANAGEMENT SERVICES,CONSTRUCTION & EXPANSION OF DESALTING UNITS |

| 24 | SEPANIR OIL & GAS ENGINEERING CO | FRONT END ENGINEERING DESIGN ,DETAILED ENGINEERING AND PROCUREMENT SERVICES.SOUTH PARS FIELD DEVELOPMENT ,PHASES 15&16 |

| 25 | ARAK PETROCHEMICAL CO | CONSTRUCTION SUPERVISION,75000 T/Y OF LLDPE PLANT IN ARAK PETROCHEMICAL COMPLEX |

| 26 | N.I.O.E.C. | BASIC ENGINEERING.TABRIZ SHAHRIAR REFINERY-NEW 110000 B/D REFINERYAND ITS INTEGRATION TO THE EXISTING REFINERY |

| 27 | OIL DESIGN AND CONSTRUCTION COMPANY | BASIC DESIGN REVIEW, DETAILED ENGINEERING, PROCUREMENT ENGINEERING SERVICES. TEHRAN REFINARY PRODUCT UPGRADING |

| 28 | NIOC-CENTRAL OIL FIELDS CO. | PROJECT MANAGEMENT (MC) SERVICES,SOUTH GASHOY GAS FIELD DEVELOPMENT |

| 29 | PETROIRAN DEVELOPMENT COMPANY | CONCEPTUAL STUDY AND BASIC DESIGN, JUFEYR OIL DEVELOPMENT FIELD |

| 30 | SEPAHAN OIL COMPANY(SOC) | BASIC AND DETAIL ENGINNERING, PROCUREMENT SERVICES, CONSTRUCTION MANAGEMENT- REVAMP OF THE EXISTING MEK UNIT AND ESTABLISHMENT OF NEW WHITE OIL UNIT |

International Cooperation

To keep up with the pace of technology and for effective utilization of specific knowhow in implementation of projects, NARGAN collaborates with a number of reputable international companies, either through joint ventures or on subcontracting basis. Some of the international companies NARGAN has cooperated with include the following:

Axens IFP Group Technologies, Balfours, Basell Polyolefins (Currently Lyondellbasell), BP, Chiyoda Corporation, Didier Engineering, Eurotecnica, Foster Wheeler, Haldor Topsøe, Iran Pan-American Oil Co. (IPAC; Iran & USA JV), John Brown Deutsche Engineering, KBC Process Technology, Kinetics Technology (KT; formerly Technip KTI), Klöckner Stadler Hurter (KSH), Linde Group, Lurgi (Currently Air Liquide), Nexant, Pipeline Technologies Inc., Prosernat IFP Group Technologies, Rollechim Impianti, Snamprogetti (eni), Société Irano-Italienne des Pétroles (SIRIP; Iran & Italy JV), Société Française de Pétroles d’Iran (SOFIRAN; Iran & France JV), Stamicarbon, Technip (Benelux, France, Italy, Germany, etc.), Tecnimont, The Shawinigan Engineering, Total, Towlid Rowghan Refining Co. (Iran & USA JV), Uhde (Currently ThyssenKrupp Industrial Solution), Versalis (eni; Formerly Polimeri Europa) and many more.